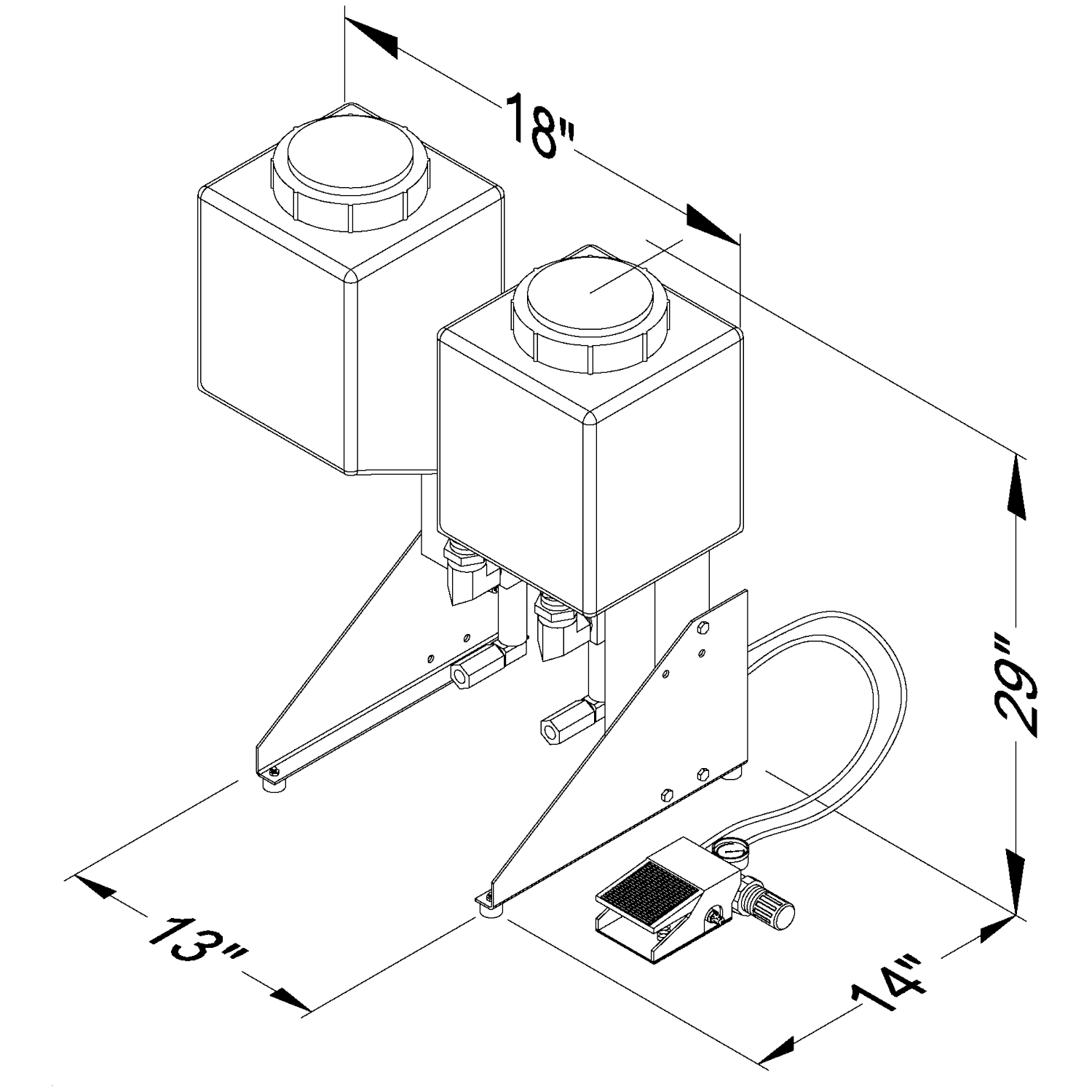

Description

When to choose the Pump-kin

The Pump-kin is a small light duty machine. It is at its best when running short run production/lab batch parts larger than 5cc but not so large that the manual controls make the operation tedious.

The low cost and small foot print of the Pump-kin make it the best fit for many light industrial applications.

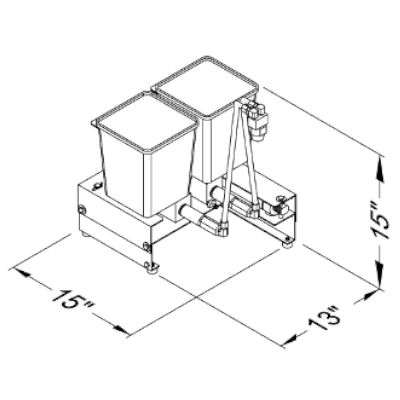

The Pump-kin is the smallest of our air powered machines. Intended for lab or short run production work It will pump most self-leveling resins. The output is 14cc per stroke, approximately one pound per minute. One full or partial stroke with each press of the foot pedal. Ratios from 7/100 to 1/1 are available. The output speed is adjustable with the supplied air pressure regulator.

As with all of our machines with single acting pumps the Pump-kin is available in two configurations:

The vertical machine for moisture sensitive urethane and methacrylate materials. The vertical configuration includes wet cups around the piston rods to keep material from sticking to the piston rods and damaging the seals, and desiccant filters to remove any moisture from the air that is vented into the reservoirs.

The Horizontal machine for epoxy and silicone, materials that are not moisture sensitive.

In addition to the base models there are several options available:

6’ hoses, mechanical stroke length limit, vacuum degassing tanks, reservoir and pump heaters.