Description

When to choose the Super E

The Super E is the best choice for most potting, filter, and casting applications. The exceptions are when the parts are large and the required flow rate exceeds 3lb/minute (low viscosity). The Super E is a straight forward winner in the overly complex world of industrial meter mix equipment.

Specifications

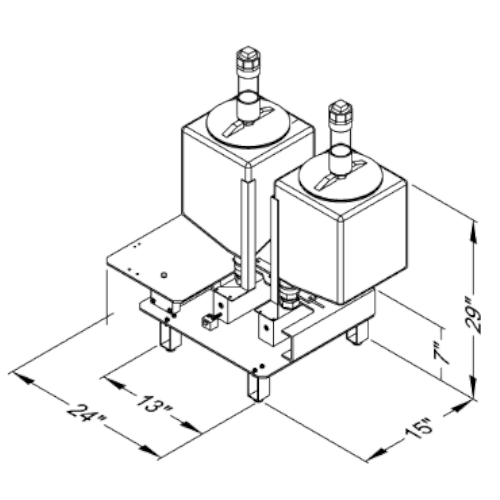

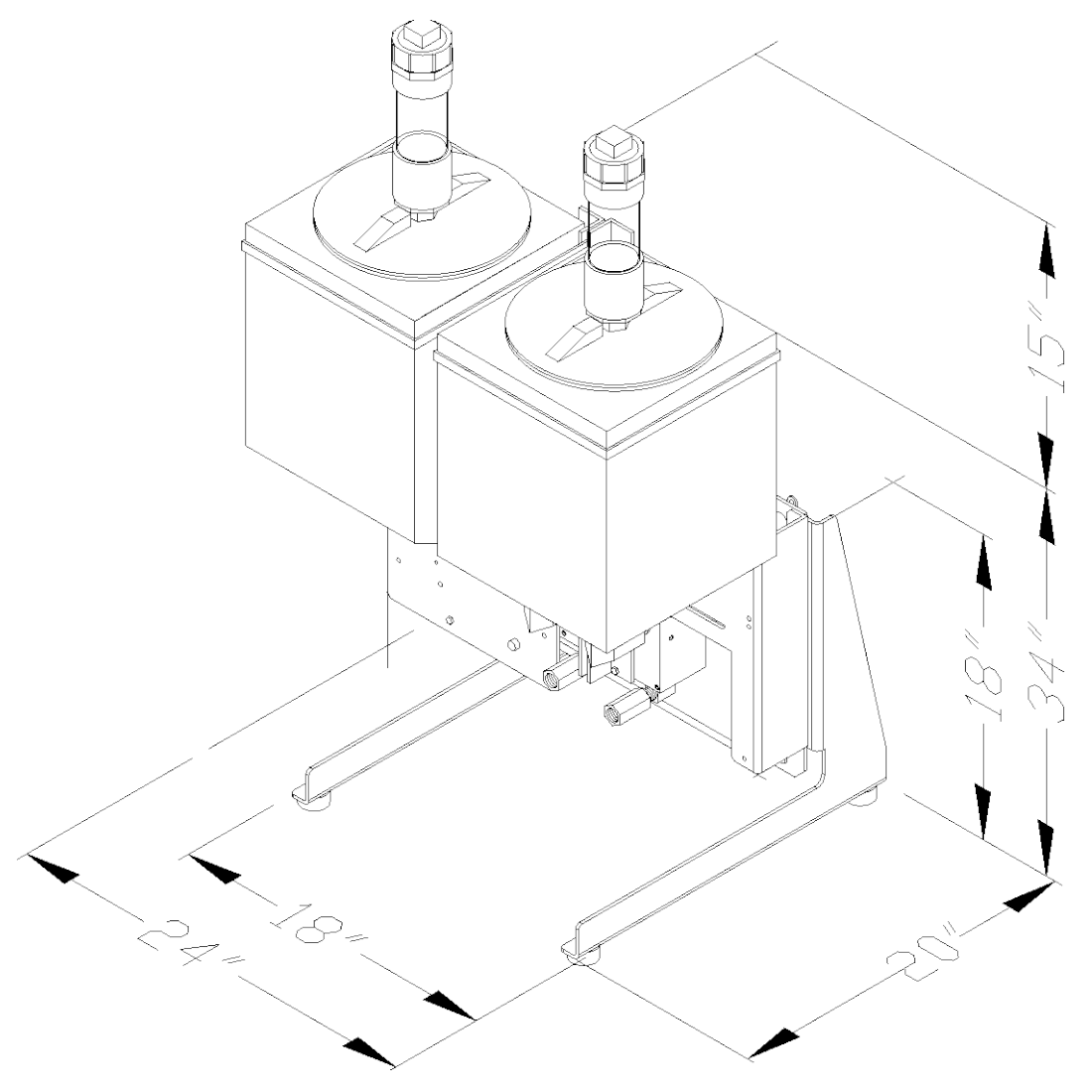

- Type: Compact, pneumatically operated bench top meter mix dispense system.

- Dispensing Capability: Up to 3 lbs. of mixed resin per minute (low viscosity).

- Pumps: Durable, accurate piston pumps with abrasion resistance, hardened parts, and wear take-up seals.

- Material Compatibility: Suitable for all self-leveling materials.

- Standard Features: Includes nine-foot hoses, a mixer gun with disposable static mixers, spare parts, an extra instruction manual, and accessible technical support.

- Ratio Ranges: Comes preset within one of four ratio ranges, fully adjustable within that range, covering ratios from 6:100 to 1:1.

- Versatile Ratio Adjustment System: Enables simple and accurate ratio adjustments for diverse application requirements.

Configurations

- Vertical machine: for moisture sensitive urethane and methacrylate materials. The vertical configuration includes wet cups around the piston rods to keep material from sticking to the piston rods and damaging the seals, and desiccant filters to remove any moisture from the air that is vented into the reservoirs.

- Horizontal machine: for epoxy and silicone materials that are not moisture sensitive.

Available Options

- Snuff Back Gun: Allows instant flow stoppage for quick, clean transitions to the next part.

- Electronic Shot Size Control: Encoder-based control with memory locations, Auto Repeat, and Purge Timer functions.

- Heaters: Available for reservoirs, pumps, and hoses to maintain optimal material viscosity.

- Agitators: Both pneumatic and electric options to maintain material consistency.

- Support Equipment: Includes carts, drum racks, tote stands, vacuum degassing tanks, and supply pumps.

- Level Sensors and Controls: For monitoring and managing the material supply.