Pro Meter for Urethanes

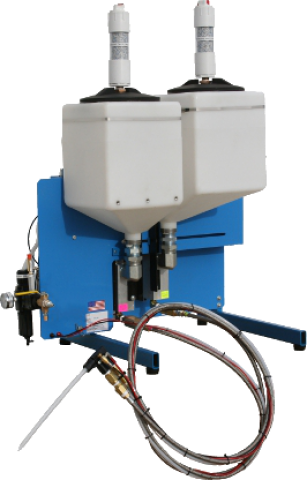

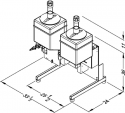

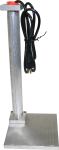

Vertical Pro Meter

The Pro-meter is a compact, highly versatile, industrial dispensing machine.

Appropriate for electronics potting, filter end capping, urethane casting, filament winder and roll coater bath supply. It also excels in many other medium to larger sized applications.

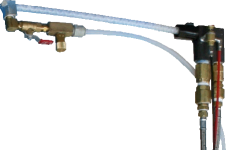

It accurately dispenses metered and mixed material through a static mixer manifold.

The dispense rate is adjustable from a gentle flow up to one gallon per minute.

The ratio is easily adjustable with a sliding ratio adjustment block.

Capable of dispensing ratios from 2:100 to 100:100, and materials with viscosities from 1cps to 200,000cps+ if self-leveling.

Standard delivery of material is thru 8 or 13gal day tanks but the Pro-meter can also be easily configured to deliver the material thru 55-gallon drums, totes, or vacuum degassing tanks.

The Vertical Pro Meter is for used with moisture sensitive materials, like Urethane, Methyl acrylates and some high-performance epoxies.

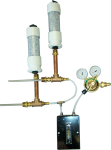

The Vertical configuration includes wet cups around the piston rods to keep material from sticking to the piston rods and damaging the seals. It also comes with desiccant filters to remove any moisture from the air that is vented into the reservoirs.

The Horizontal machine is typically used for epoxy, silicone, that are not moisture sensitive.

There is a long list of options for the Pro Meter including:

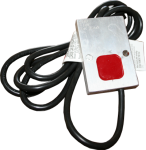

- Snuff Back Gun: Stops the flow of material instantly allowing the operator to quickly and cleanly move to the next part.

- Electronic Shot Size control: Encoder based shot size control with memory locations, Auto Repeat and Purge Timer functions.

- Heaters for the reservoirs, pumps, and hoses.

- Agitators, both pneumatic and electric.

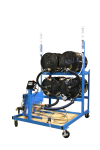

- Carts, Drum Racks, Tote Stands, Vacuum Degassing Tanks, and Supply Pumps.

- Level sensors and controls to keep track of and manage the material level.

When to choose the Pro Meter:

The Pro Meter is designed for casting, potting, and laminating.

The Pro Meter excels at many related applications such as: coil impregnation, filter end capping, vacuum casting and potting.

With an output of 1 gallon per minute (low viscosity) the Pro Meter is the best choice when the parts are large or there is a requirement for higher flow rates.

The Pro Meter is relatively tolerant of abrasive fillers and materials that may not be perfectly clean.

The Pro Meter is the go-to machine when working with difficult ratios and hard to mix materials.

Product Options

Product Media

| Filename | File size |

|---|---|

| ProMeter.pdf | 312.21 KB |