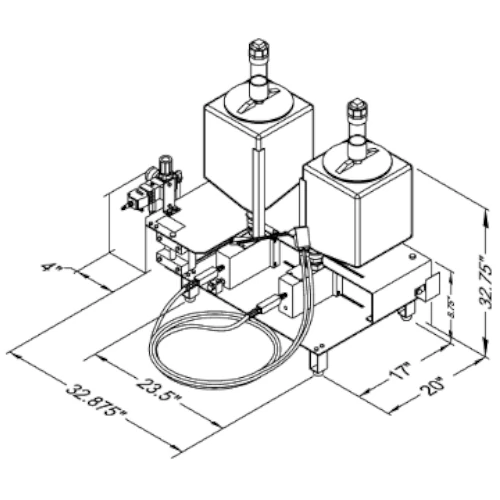

Description

Pro Meter: Industrial Dispensing Solution

When to Choose the Pro Meter: Ideal for a broad spectrum of applications, the Pro Meter shines in casting, potting, laminating, coil impregnation, filter end capping, vacuum casting, and potting scenarios. It’s the perfect fit for large parts or situations requiring high flow rates, offering unparalleled versatility with an output of 1 gallon per minute for low viscosity materials. Notably efficient with abrasive fillers and less-than-clean materials, the Pro Meter tackles challenging ratios and complex material mixes with ease, making it a preferred choice for a wide range of industrial dispensing needs.

Specifications:

- Type: Compact, industrial-grade dispensing machine, available in pneumatically operated configurations.

- Dispensing Capability: Adjustable gentle flow up to 1 gallon of mixed material per minute.

- Ratio Adjustment: Sliding ratio adjustment block allows for precise control, offering ratios from 2:100 to 100:100.

- Material Compatibility: Capable of handling materials with viscosities from 1cps to over 200,000cps+, provided they are self-leveling.

- Standard Features: Delivery through either 8 or 13-gallon day tanks, with options for 55-gallon drums, totes, or vacuum degassing tanks for material delivery.

- Pumps: Precise piston pumps designed for both high and low viscosity materials, featuring solvent cups on pumps to enhance seal life and minimize downtime.

Configurations:

- Vertical Machine: Best for moisture-sensitive materials like urethane, methyl acrylates, and some high-performance epoxies. Includes wet cups and desiccant filters to protect against moisture.

- Horizontal Machine: Suited for epoxies and silicones that are not moisture sensitive.

Available Options:

- Snuff Back Gun: Enables instant material flow stoppage for seamless transitions.

- Electronic Shot Size Control: Features encoder-based control with memory, Auto Repeat, and Purge Timer functions.

- Heaters: Ensure optimal viscosity by heating reservoirs, pumps, and hoses.

- Agitators: Available in both pneumatic and electric variants to maintain material consistency.

- Support Equipment: Includes carts, drum racks, tote stands, vacuum degassing tanks, and supply pumps.

- Level Sensors and Controls: Monitor and manage material supply efficiently.

Versatile and Robust: The Pro Meter’s comprehensive design and broad range of capabilities make it an essential tool for industries requiring precise, reliable, and efficient dispensing solutions. Whether dealing with intricate electronic components or large-scale industrial projects, the Pro Meter delivers with accuracy and adaptability.