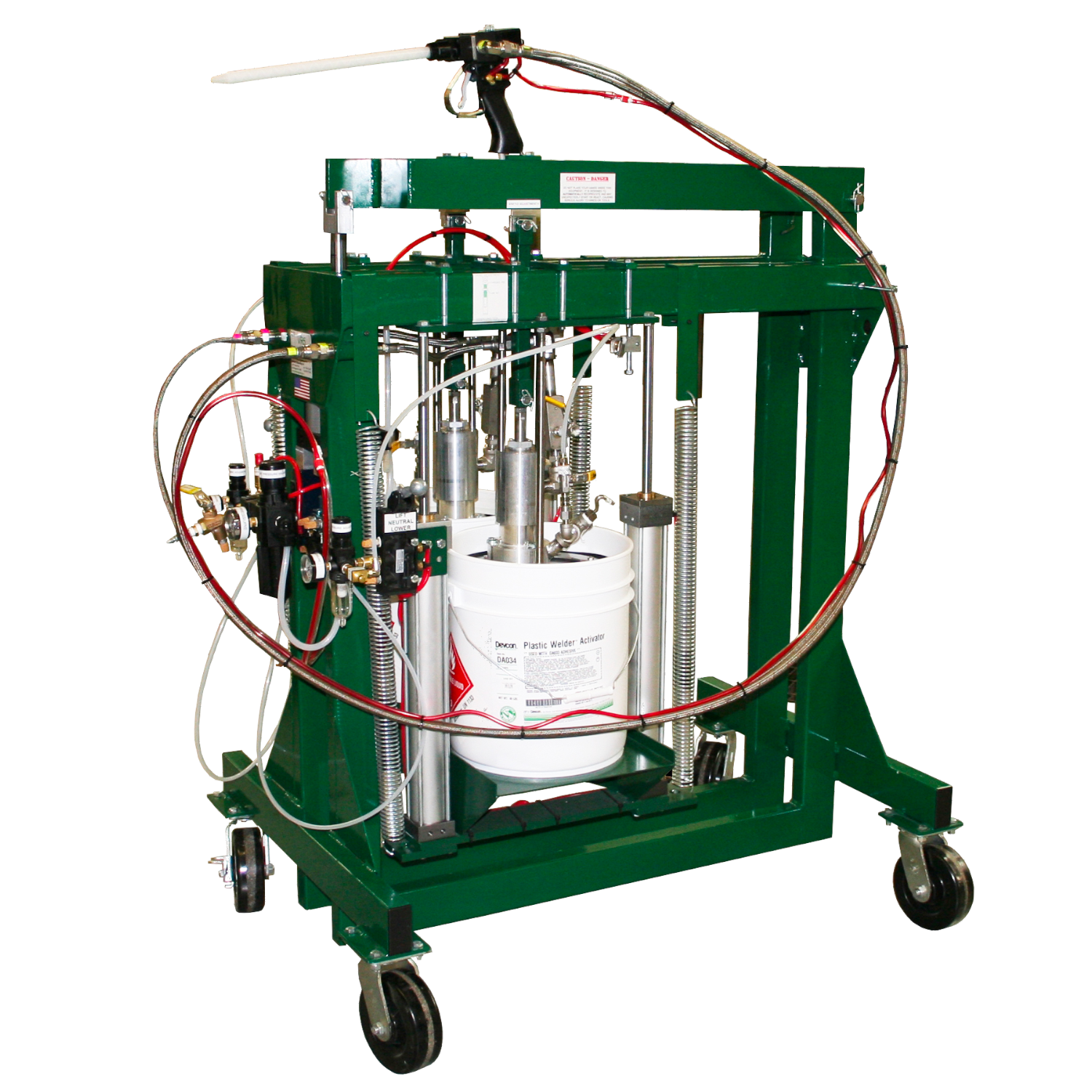

Description

When to use the VR-5

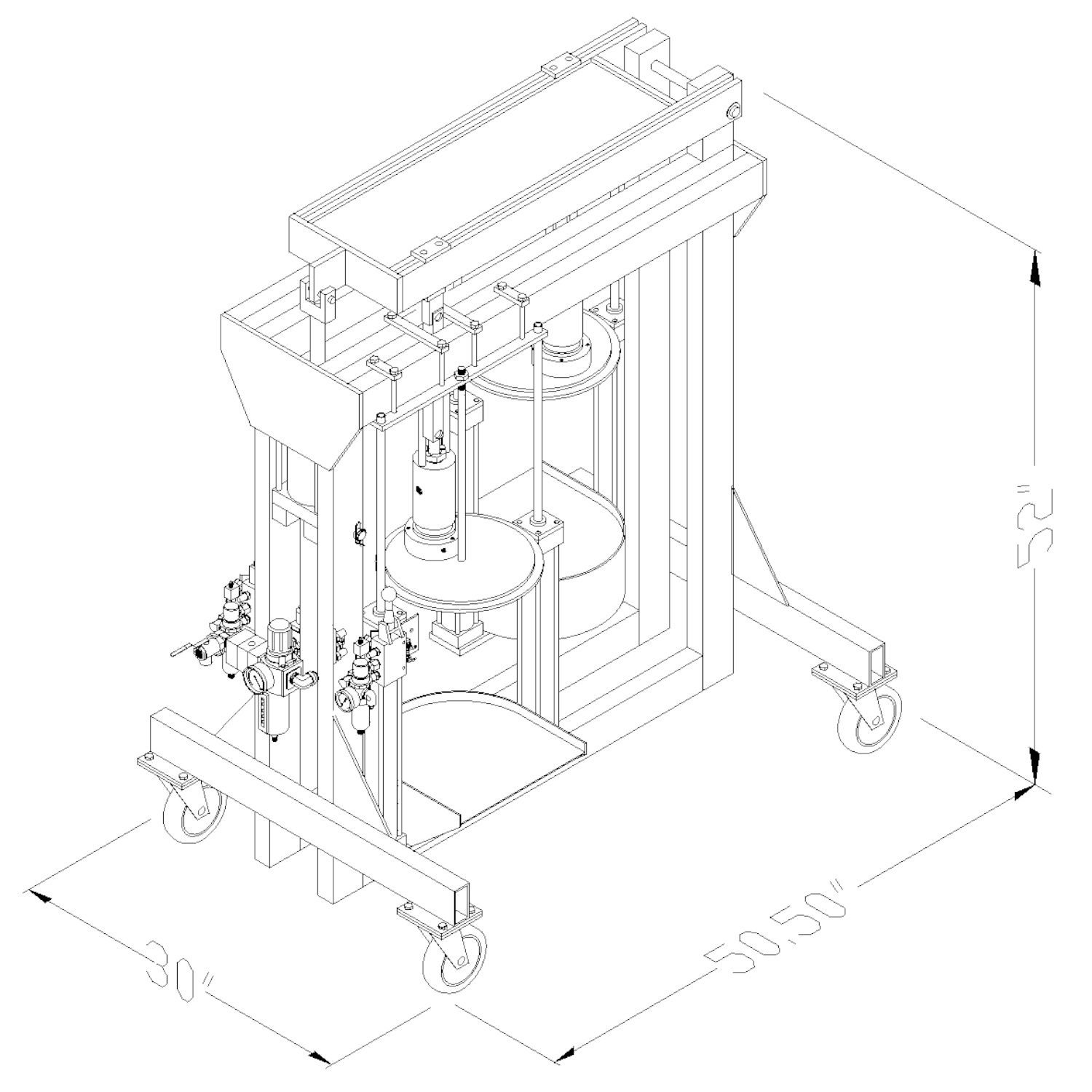

The VR-5 pumps directly out of 5 gallon, open head shipping containers. Dual cylinder rams ensure positive material feed. A hand gun with snuff back ensures accurate, clean adhesive placement. Simple, durable piston pumps ensure long life and easy maintenance. The VR-5 has a robust twin lip ram plate for an effective leak-resistant seal.

Specifications:

- The right machine for paste materials

- Handles very difficult, moisture sensitive, or abrasive materials

- Reduces material handling, no messy transfer of materials

- Pumps directly from 5 gallon shipping container

- Compatible with, epoxies, silicones, methacrylates, urethanes, and acrylics

- Very flexible, easy slide ratio adjustment. Ratios from 20:100 to 1:1

- Dispenses a wide range of viscosities, from thick liquids to paste

- Eliminates weighing/mixing errors

The VR5 can be fitted with additional components, including:

- Snuff Back Gun, Stops the flow of material instantly allowing the operator to quickly and cleanly move to the next part.

- Manifold can be rigid mounted or installed on custom length hoses.

- Electronic Shot Size control, Encoder based shot size control with memory locations, Auto Repeat and Purge Timer functions.

- Low material level shut down.

- Safety Cage

- Methacrylate-safe Stainless Steel Wetted Parts.